Everything about LG robot CLOi told by robot developers of LG Electronics

What is your image of robot like? In movies, robots fly around saving the earth. But in reality, it is only a recent thing that robots became able to live with humans identifying its location and avoiding obstacles. It still has a long way to go, but robot has an infinite possibility. We met with Researcher Lee Sung-bum in charge of robot business, Director Hong Jae-myung and Team Leader Kim Ji-hyung of BS Division in LG Electronics, who are making our lives more convenient and safer through the robot technologies.

(From left) Research Fellow Lee Sung-bum in charge of robot business,

Product Development Director Hong Jae-myung, Business Support Team Leader Kim Ji-hyung of LG Electronics

Researcher Lee is an expert in vision AI who oversees the robot driving technology research. Director Hong is in charge of robot product development as well as development of robot tools and hardware systems. Team Leader Kim establishes business technology strategies and provides support for all parts related to robot business to operate smoothly.

Beyond technology and closer to humans

It was not until 2017 CES (Consumer Electronics Show) that LG Electronics started introducing robots in earnest. Back then, the robots were the results of advance research, but the next year the company successfully finished a national project to build guide robots for Incheon International Airport. This was when LG’s robots became known to the outside world. In 2019, Robot Business Center launched under immediate supervision of CEO and started full-fledged R&D of robots. This year, Robot Business Center was incorporated into Business Solutions (BS) Division, adding sales abilities and global distribution network to the technological capabilities accumulated thus far.

Research Fellow Lee Sung-bum of Robot Driving Team

Q. How advanced is the current robot technology

and how are robot development and business of LG Electronics coming along?

Lee Sung-bum: People might expect to see robots that can think and act for themselves, like Taekwon V and Atom, but the commercialized robots at the present are elementary compared to those. The current commercialized robots cannot replace humans completely but can assist humans. Currently, Robot Business of LG Electronics mostly focuses on developing and launching commercial service robots that are based on the driving technology. Main ones are LG CLOi guidebot and servebot.

Kim Ji-hyung: From business perspective, we are at the stage where we are looking for feasible areas for commercialization, and for some of our efforts we are seeing visible results. Although our products in this area is not as well-known to the outside world as others, we have been strengthening our capabilities since 2017, so we are confident that we have the best capacity to mass-produce robots in the country.

Team Leader Kim Ji-hyung of Business Support Team

Q. Since mass-producibility has been brought up,

what do you think are the most essential elements for mass-producing robots?

Hong Jae-myung: There is a big difference in quality between prototypes and robots that can actually be used on the site. What is important is how reliable and safe the product is. We need to be equipped with technological capabilities and quality management process to guarantee this.

From its past experiences in home electronics and mobile fields, LG Electronics has accumulated both hardware capability and software capability and also capability of quality management suited to customers. The company already has much experience in developing service robot technologies and mass-producing and applying robot products based on such capabilities. In this regard, I think we are moving forward quite fast.

Director Hong Jae-myung of Product Development Department

Q. What kinds of robots have been commercialized so far? What was market reaction like towards these robots?

LG Electronics’ robot portfolio (LG CLOi servebot, guidebot, baristabot)

Kim Ji-hyung: We have commercialized intelligent service robots for guide, serving, delivery, disinfection and cooking, and these are being used in places like restaurants, hotels/resorts, hospitals and large shopping malls. In hospitals, for example, these robots are doing delivery of specimens and drugs for the medical teams, reducing the workload and helping the personnel focus on patient care. The satisfaction level is high. Since it is not yet easy to see commercialized robots around, hospital visitors are quite amazed by them, and they often talk to the robots or even name them, showing positive reactions. Naturally, the robots became like hospital mascots.

Lee Sung-bum: Recently, we are piloting second-generation guide robots in COEX mall in Samsung-dong, and many of our developers are going out to the site to check out the reactions. We see so many people showing interest, coming to the robots to talk to them and using the built-in photo-taking feature.

Second-generation LG CLOi GuideBot won the Minister of Trade, Industry and Energy Award in the 2021 Good Design Korea.

We build the smartest and safest robots.

Unlike regular home electronic products that are installed or fixed in one spot, service robots need to keep moving around according to the needs. For this reason, the driving technology is a key in robots. LG robots have the Vision SLAM technology, which applies AI to the existing location awareness technology, and thus have a much superior driving capability than other companies’ products.

Researcher Lee is explaining a servebot that has the Vision SLAM technology, a proprietary driving technology of LG Electronics.

Researcher Lee is explaining a servebot that has the Vision SLAM technology, a proprietary driving technology of LG Electronics.

Q. Could you explain the driving technology built in LG Electronics robots?

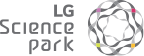

Lee Sung-bum: For a robot to self-drive, it needs to know where it is now and to where it is going. For this, most commercial robots rely on markers attached on the ceiling to find out its current location. However, if the ceiling is too high or rugged, location awareness using markers becomes useless. The second most used technology is Lidar where the robot shoots laser into a wall to identify the distance to the wall and avoid obstacles. The problem with this method is that the recognition rate drops in an environment with severe diffused reflections or with glass walls.

Comparison between marker method and Vision SLAM

When the robot moves around indoors, it uses a technology called SLAM (Simultaneous Localization and Mapping) to map out the space and use the map to locate itself. LG Electronics added the AI technology to this to create the Vision SLAM technology which enables the robot to find out its location using images photographed by the camera in the same way that human eyes recognize the environment. Robots with Vision SLAM have higher driving capability than other companies’ products. As an example, an LG delivery robot was once deployed to a place where other robots could not travel and finished the job successfully when we were working with a delivery service company. Vision SLAM is LG Electronics’ proprietary technology which other companies have not been able to commercialize yet.

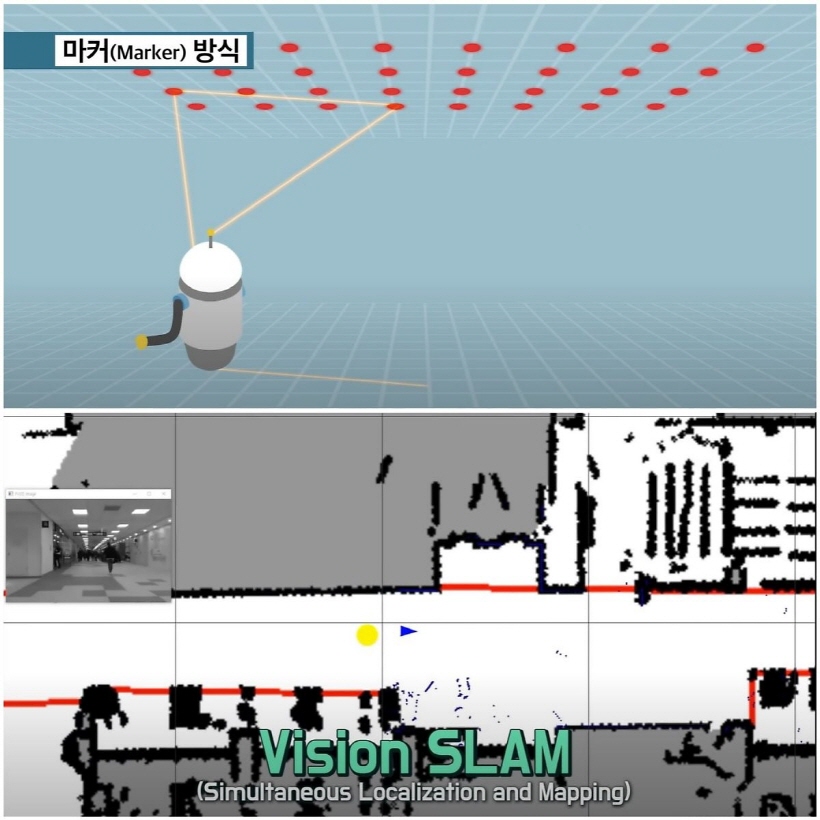

Q. Robots are said to require a combined technology. What technologies are included here?

Hong Jae-myung: A person uses bones and muscles to walk and the five senses to avoid obstacles, decide which way to take, and talk to someone nearby. It’s the same with the robot. To make this possible, we need to design robot tool structure, driving circuit, sensor circuit and processing system that receives and processes data and also apply software algorithms like AI. We also need a cloud system for advanced movements and communication with other robots. In this regard, robot is integration of all technologies.

Various modules and technologies in a robot

It is rare to see such a product with so many technologies integrated into one. If we can advance the robot technology and gain insights, we will be able to make washing machines and refrigerators smarter in future. For example, we can attach wheels to an air purifier and let it travel around to wherever the air quality is not good and attach arms to a washing machine and make it take out the wet laundry when washing is over. In the end, the robot technology will be connected to the home electronics that we commonly use.

Director Hong has been in robot development from the first-generation LG CLOi guidebot.

A shot with the guidebot he cherishes like his own child

Q. What is the most difficult thing in robot development? Are there any aspects that require special attention unlike in home electronics development?

Lee Sung-bum: Robot’s performance and safety often conflict with each other, and it is very difficult to develop the technology trying to meet the high internal quality standards and safety considerations at the same time. However, the most important thing in development is safety. The reason why we make robots is to make people’s lives more convenient and richer, so it’s nonsense that our service should endanger anyone in any way. The biggest challenge now is to prioritize safety first and then maximize performance.

Kim Ji-hyung: In the case of home electronics, the market is already opened up, and products have been sold to customers for a long time, so it is easier to identify customer needs and USP (User Selling Point) that require improvement or more focus. However, with robots, it’s not always easy to find customer needs or improvement points since many of the technologies are newly used and we need to continue to find markets.

Hong Jae-myung: Once a product or business matures, the related parts businesses also grow. Then, more options become available, and as better and cheaper parts are developed and used, product development becomes easier. However, the robot products, markets and services are still in their early stages, so there are not enough parts and sensors designed just right for us to implement the services we want. So, during development, we always need to take this into account, and there are a lot of things to review such as standards and regulations. Also, there are a lot of things to do to ensure quality, such as verifying the new products and services. With that said, we are making efforts in all areas including marketability, services, development and quality, and I think the process will be more stabilized with time and experience,

“My role is to provide support for all parts of robot business to run smoothly.” Team Leader Kim Ji-hyung of Business Support Team

“My role is to provide support for all parts of robot business to run smoothly.” Team Leader Kim Ji-hyung of Business Support Team

Q. Could you tell us LG Electronics’ development directions and future plans for its robots?

Lee Sung-bum: Starting with guide robots, LG Electronics’ development of service robot technology has centered around delivery. We applied the shared driving platform, and a variable part on top of it that differs according to the purpose, such as delivery, guide and serving. Goals of robot technology development are so many that we cannot even say for sure now, but our next goal is to build a delivery robot that freely travels between indoor and outdoor areas.

Hong Jae-myung: We started with robots that were just simple machines, but from software and service perspectives, we are now developing smart robots with intelligence. One aspect to consider is how we are going to interpret and judge the information that comes in through various sensors and robot movements, and another is how, from a perspective of effectiveness, we can use a single robot platform to build various robots quickly rather than build a product individually each time for a service or goal. We are doing a lot of thinking to provide practical robot services. We are planning to develop our robot technology in three directions: build intelligent robots through software, apply common platform to develop and provide various services more quickly, and combine these two to build solutions.

We paint the picture of robots in LG Sciencepark.

Our robot business started in 2017 with a small number of people under the project name “living robot task,” and now it has grown into Robot Business Division. Afterwards, the division’s personnel who had been scattered in Youido, Gasan and Magok gathered into Magok LG Sciencepark at the end of 2019. As the workers can work together in the same building, communication and collaboration became much easier, and they are much more satisfied.

Q. What do you like better after your team moved to LG Sciencepark?

Lee Sung-bum: Before moving here, teams that worked on the same thing were in different locations, but now they are all in the same complex and the same building, which makes collaboration much easier. It was inconvenient to have to go to another department when there is an issue or thing to be discussed, but now it’s much easier.

Hong Jae-myung: There are some people whom I used to work with but could not see as often after the teams changed. But I met them here again, so I am happy. Another thing is that newly formed teams like ours sometimes do not have what we need such as like expensive large-scale development equipment or research environment for verification and maintenance, but here we can use equipment of other teams or ask for some help.

Kim Ji-hyung: Most of all, I like the fact that I have a bigger desk here. And the working environment is very fresh. I especially like the atmosphere of Convergence Road that runs straight between the buildings. When I walk on the road after work on Friday afternoon, it feels like that I am somewhere else than the company premises.

Q, How would you describe LG Sciencepark in one word or sentence?

Lee Sung-bum: “A place that I can boast to others.” Google has Google Campus. I hoped that LG would have some representative place that I can show off to other people, but now I can proudly show LG Sciencepark as the core research complex to other people that I get to work with.

Hong Jae-myung: “Come together. Let’s give it a shot!” This is what LG Sciencepark feels like to me. The entire Robot Business Division of LG Electronics literally gathered in one place, so now what’s left is to give it all we've got. (laughter)

Kim Ji-hyung: “Caring mind towards researchers” Our previous-generation management built this place to provide great environment to the researchers. I can feel that caring mind everywhere from the walking path to the botanic park. I think this place reflects LG’s business philosophy that focuses on research and values technology.

Q. Please share with us your future goals and plans while working in LG Sciencepark.

Hong Jae-myung: Since we started to work on commercialization in earnest after arriving here, we want to make the robot business succeed and grow so that we can contribute technologically and also business-wise to LG Electronics. As a researcher, I want to see the robots we build becoming a friend to consumers. The most noticeable feature of our robots is their eyes. I want to build robots that can help people in need of help and empathize with and console them through eye contact.

Kim Ji-hyung: Since our work is a new business, we cannot see the results right away. But many people encourage us, sometimes with feedback. To meet such expectations, we are trying hard to get the results we want. As part of Business Support Team, I will provide my best support to help those working in development, product planning and sales.

Lee Sung-bum: Many people worry that robots will rob humans of their jobs, but in fact robots are sometimes not good at what people do easily and good at things people struggle with. I want to contribute to enriching people’s lives with robots that do difficult or dangerous jobs for people and free them up for more valuable jobs, rather than replace humans or take jobs away from them.